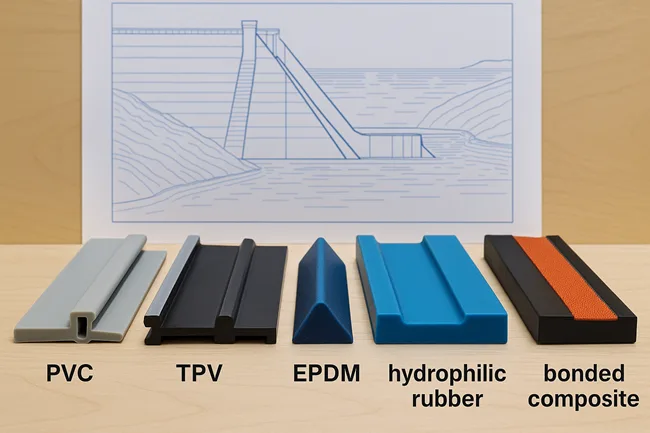

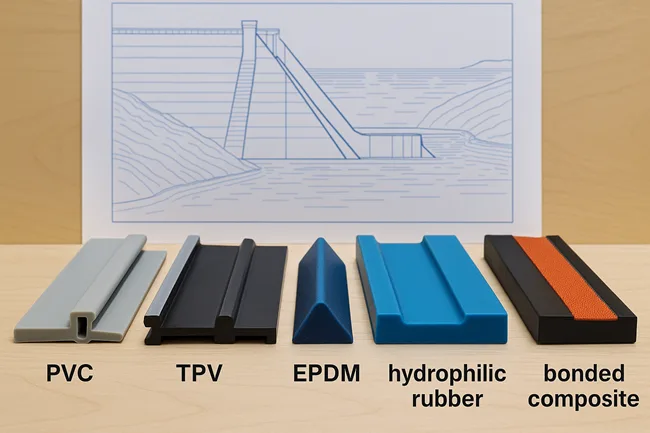

As dam retrofitting accelerates worldwide—driven by aging infrastructure, rising hydrostatic stress, and climate variability—the demand for durable, movement-capable waterstop systems has never been greater. Whether embedded in new gravity dams or retrofitted into decades-old monolith joints, waterstops play a crucial role in preserving structural watertightness. While many local suppliers provide off-the-shelf profiles, large dam projects increasingly turn to a short list of globally trusted manufacturers known for engineering-grade performance, regulatory compliance, and customization support.

Who are the leading waterstop manufacturers supplying products for large-scale dam infrastructure?

These five companies stand out for their long-standing credibility, broad project footprint, and ability to meet the demanding conditions of concrete dam sealing:

Sika AG (Switzerland) is among the most recognized brands in civil infrastructure waterproofing. Its Sikadur-Combiflex SG system is often used in dam joints due to its chemical resistance, flexibility under joint movement, and compatibility with both new and aged concrete. Sika also offers a range of PVC, rubber, and hydrophilic waterstops certified for potable water structures, including those compliant with NSF/ANSI standards. The company has supported sealing in projects such as hydropower stations, large spillways, and DRIP-aligned Indian dams.

Trelleborg Ridderkerk BV (Netherlands) specializes in engineered waterstop systems designed for extreme hydrostatic pressure and joint movement. Its Omega, Omega DS, and W9 series are widely specified for use in concrete monolith joints, tunnels, and high-head dam galleries. Trelleborg also manufactures large-format EPDM-based profiles designed for joints with wide displacement tolerances, making them suitable for dams in seismic or high-altitude environments. These systems are factory-vulcanized and often pre-fabricated to fit complex joint geometries, reducing installation error and field adaptation requirements.

GCP Applied Technologies (United States), formerly part of W.R. Grace, offers several high-performance systems for below-grade and water-retaining infrastructure. The PREPRUFE and SERVITITE product ranges are commonly used in dam galleries and foundation joints. GCP’s hydrophilic waterstops are especially popular in retrofits, where swelling action helps seal irregular joints without requiring full surface re-profiling. The company’s products are used extensively in U.S. Army Corps of Engineers projects and are gaining market share in emerging hydro retrofit projects across Southeast Asia and Latin America.

Fosroc International (U.K./India) is a staple in South Asia and the Middle East, particularly in projects funded by the World Bank and local infrastructure ministries. Its Supercast range, including both PVC and hydrophilic waterstops, is engineered to meet Indian BIS standards and international codes. Fosroc is also known for supplying injectable sealing compounds and adhesive-bonded joint systems suitable for post-construction dam rehabilitation. Its widespread use in DRIP-supported dams across states like Tamil Nadu, Maharashtra, and Himachal Pradesh speaks to its localized engineering support and government procurement footprint.

Kryton International Inc. (Canada), operating under the Krystol brand, is best known for its crystalline waterproofing technology, but it also offers waterstop solutions for high-risk hydraulic structures. The Krystol Waterstop System integrates crystalline admixtures with external sealing profiles, providing self-sealing properties that work especially well in chemically aggressive or groundwater-influenced environments. This approach is gaining traction in concrete dams built near industrial zones or coastal areas where water chemistry presents long-term sealing challenges.

Why do these manufacturers dominate in high-risk infrastructure sealing?

High-head dams, spillways, and reservoir structures expose waterstop materials to immense hydrostatic pressure, joint displacement, and long-term immersion. The five manufacturers listed above differentiate themselves through a combination of time-tested field performance and strong technical credentials. Each has decades of proven success in government-led and multilateral-funded dam infrastructure projects, often supported by global or regional compliance with engineering standards such as ACI, BS, IS, ASTM, and NSF.

What further sets them apart is their investment in in-house research and proprietary formulations—particularly in the areas of hydrophilic swelling compounds, elastomeric bonded membranes, and large-profile flexible joint systems for dynamic movement. In addition, they offer full-service support that goes beyond manufacturing. These companies maintain global or regional technical teams to assist contractors and engineers with installation planning, on-site adaptation, and quality assurance protocols, ensuring that waterstop systems integrate properly into complex project workflows.

How should dam operators evaluate waterstop vendors in 2025?

For dam owners and EPC contractors, evaluating waterstop vendors in 2025 means thinking beyond catalog specs. The most resilient sealing strategies are those that align product compatibility with site-specific engineering. Waterstop profiles must be matched to the type of joint being treated—whether expansion joints, monolith separation gaps, lift joints in RCC dams, or construction interfaces. A poorly matched profile can lead to suboptimal sealing performance, even with a high-quality product.

Equally important is verifying material compatibility with the dam’s hydraulic environment. Engineers should confirm chemical resistance and swelling capacity under site-specific reservoir conditions, especially in cases where brackish water, high alkalinity, or silty inflows may be present. Additionally, the chosen waterstop should be suitable for the intended installation method—whether embedded in new concrete, surface-bonded in retrofit conditions, or injected into existing gaps using polyurethane or other systems. For projects in geologically active or high-altitude zones, preference should be given to vendors with documented performance in similar climates and stress profiles, as this ensures material reliability over long design horizons.

Ultimately, waterstop failures are expensive—not just because of leakage, but because of the inspection, downtime, and remediation required. Working with proven, large-scale suppliers ensures that the material behind the joint performs as reliably as the concrete around it.

Discover more from Business-News-Today.com

Subscribe to get the latest posts sent to your email.