Why are Mitsubishi Chemical Group and Boston Materials partnering to solve the semiconductor industry’s thermal crisis?

Mitsubishi Chemical Group has set the stage for a significant evolution in the semiconductor packaging industry by entering into a strategic partnership with Boston Materials, Inc. This collaboration, announced in December 2025, revolves around the development and commercialization of advanced thermal interface materials for high-performance computing and artificial intelligence data center applications. Mitsubishi Chemical Group, recognized worldwide for its role in advanced materials, is investing in Boston Materials through its U.S. corporate venture arm, Diamond Edge Ventures, and positioning itself at the heart of a sector grappling with the limits of traditional thermal management.

The alliance is widely seen as a bid to ensure Mitsubishi Chemical Group remains a primary supplier for the next generation of chips and systems. Industry analysts are interpreting the partnership as a deliberate response to growing market pressures for innovative cooling solutions. Boston Materials’ expertise in energy transfer materials, particularly its Liquid Metal ZRT product line, is being leveraged to address critical thermal bottlenecks that are now among the chief obstacles to greater performance and reliability in AI data center infrastructure.

How does Boston Materials’ Liquid Metal ZRT platform aim to disrupt established semiconductor cooling technologies?

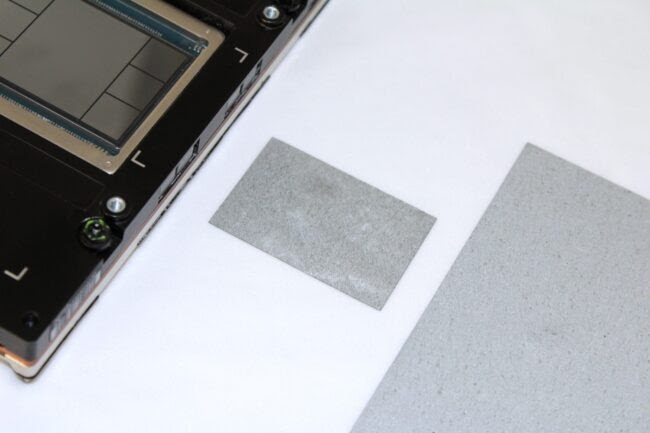

The centerpiece of this partnership is the Liquid Metal ZRT product, a thermal interface material that has already started to draw industry attention for its performance. Developed by Boston Materials using its patented Z-axis Carbon Fiber technology and proprietary liquid metal alloys, the first-generation Liquid Metal ZRT, known as LMZ1100, is credited with delivering a cooling improvement of over 10 degrees Celsius for kilowatt-scale, liquid-cooled ASICs and GPUs. These gains are particularly relevant for high-uptime, high-density applications where even minor thermal improvements can yield dramatic benefits in reliability, operational costs, and compute power.

Boston Materials is pursuing a dual strategy, focused on both performance gains and manufacturing practicality. The LMZ1100 product has been designed to support rapid integration into high-volume manufacturing processes, which is a requirement for broad adoption in the semiconductor sector. Industry insiders believe this combination of technical excellence and manufacturability gives Boston Materials and Mitsubishi Chemical Group a critical advantage in the race to supply leading-edge solutions to semiconductor manufacturers and cloud providers. The development pipeline is moving quickly toward a second-generation Liquid Metal ZRT product, which promises further enhancements in both thermal management and operational durability.

What strategic advantages does Mitsubishi Chemical Group bring to scaling liquid metal thermal materials?

Mitsubishi Chemical Group is not just providing investment capital but is leveraging its global supply chain and research capabilities to accelerate commercialization. As part of this collaboration, Mitsubishi Chemical Group is establishing new semiconductor packaging integration and application development laboratories in Asia, which is the epicenter of global semiconductor manufacturing. These new facilities will act as launchpads for pilot projects and full-scale deployment of the next-generation Liquid Metal ZRT solutions across major markets.

For Boston Materials, the access to Mitsubishi Chemical Group’s established logistics, technical support, and customer relationships in the APAC region represents a major inflection point. Semiconductor manufacturing is increasingly concentrated in Asia, and the ability to deliver technical solutions at scale to this market is expected to be a decisive factor in winning large, multinational contracts. Observers within the materials science and semiconductor industries are treating this partnership as an aggressive expansion move, one that aligns both companies with the surge in demand for AI infrastructure and next-generation compute systems.

Why is thermal management now at the center of AI data center and semiconductor performance?

With traditional methods of boosting compute performance, such as node shrinks, reaching their limits, thermal management has become the principal challenge in maintaining reliability and speed for the newest generations of chips. High-performance computing and AI training workloads continue to push the boundaries of power density and heat generation. As a result, system-level cooling innovations have become essential, but the industry is increasingly recognizing the need for materials-level breakthroughs that can deliver more effective heat transfer at the chip package level.

Boston Materials’ leadership maintains that their approach to thermal interface materials is a direct answer to this new class of challenges. The Liquid Metal ZRT platform is presented as not just an incremental improvement but a step-change solution, aiming to become the backbone of cooling architectures for next-generation AI and high-performance computing hardware. Industry sentiment points to the growing consensus that without significant advances in thermal management, the promise of ever-larger and more capable AI models will be constrained by hardware reliability and operational costs.

How are investors and institutional analysts viewing the Mitsubishi Chemical Group–Boston Materials alliance?

The strategic investment and collaboration are being received positively by both institutional analysts and technology investors, who see Mitsubishi Chemical Group’s move as part of a broader trend of advanced materials suppliers aligning closely with the semiconductor value chain. This alliance is perceived as not only addressing a current pain point but also anticipating future performance ceilings as AI and high-performance computing infrastructure investment accelerates.

Boston Materials, although privately held, is enjoying heightened credibility and commercial momentum following validation from a global materials powerhouse. The partnership is also attracting attention to peer companies in the advanced materials, thermal management, and semiconductor packaging space, with analysts expecting a spillover effect that could drive increased capital flows into these adjacent segments. Investors are particularly interested in pilot deployments with major chipmakers and hyperscalers, anticipating that successful demonstrations will be closely followed by large-scale contracts and further strategic alliances in the sector.

What makes liquid metal thermal interface materials so critical for chip packaging and AI compute?

Liquid metal TIMs are being promoted as a transformative technology in the semiconductor sector, chiefly due to their superior heat transfer capabilities compared to legacy materials. By facilitating much more efficient cooling at the package level, these solutions can directly influence the design, density, and operational stability of the most advanced AI chips and high-performance computing systems. Boston Materials and Mitsubishi Chemical Group are betting that their next-generation materials will allow customers to extract greater performance and reliability without the need for expensive, space-intensive, or complex system-level cooling upgrades.

Competitors are monitoring performance benchmarks and initial customer deployments closely, looking for signs that liquid metal TIMs could become the new industry standard rather than a niche solution. Boston Materials’ approach, which prioritizes integration with high-volume semiconductor assembly lines, is seen as key to overcoming the usual barriers to adoption for advanced materials in this highly risk-averse industry. Industry experts believe that if Boston Materials and Mitsubishi Chemical Group can consistently deliver enhanced thermal performance, durability, and supply chain reliability at scale, the competitive landscape for semiconductor packaging could shift rapidly in their favor.

What is the future outlook for the Mitsubishi Chemical Group and Boston Materials partnership as the semiconductor sector evolves?

Looking forward, Mitsubishi Chemical Group and Boston Materials appear well-positioned to set a new pace for innovation in the semiconductor and AI data center cooling market. With the establishment of new R&D and application laboratories in Asia, Mitsubishi Chemical Group is signaling its intent to become a pivotal player in next-generation semiconductor packaging. Boston Materials, in turn, is focused on rapid iteration and product development to stay ahead of both technological and manufacturing curve.

Industry analysts are forecasting that the partnership could become a template for future alliances between materials innovators and global suppliers, as the market increasingly rewards scalable, differentiated solutions that address bottlenecks across the semiconductor value chain. While the path from successful pilot to mass-market adoption involves significant hurdles, sentiment from institutional and technology strategy circles is optimistic. The coming year is expected to bring more news of large-scale deployments, with both companies looking to capture a significant share of the rapidly expanding AI and high-performance computing materials market.

The wider market impact could also include an acceleration of R&D investment in advanced materials for other high-heat, high-density applications beyond semiconductors, including electric vehicles, aerospace, and industrial automation. For now, all eyes are on the early results and customer uptake of the Liquid Metal ZRT platform as a bellwether for the future direction of thermal management innovation.

Key takeaways: What the Mitsubishi Chemical Group–Boston Materials partnership means for semiconductor thermal management

- Mitsubishi Chemical Group and Boston Materials have formed a strategic partnership focused on creating next‑generation liquid metal thermal interface materials designed to address the severe cooling challenges that continue to limit performance in high‑performance computing and artificial intelligence data center environments.

- The partnership includes a direct investment by Diamond Edge Ventures, the U.S. corporate venture arm of Mitsubishi Chemical Group, underlining a commitment to accelerate product innovation and market adoption in the semiconductor sector.

- Boston Materials’ first-generation Liquid Metal ZRT product, LMZ1100, has demonstrated more than a 10-degree Celsius improvement in cooling for kilowatt-scale ASICs and GPUs, and the next-generation product is set to offer even greater thermal and reliability advantages.

- Mitsubishi Chemical Group is establishing advanced semiconductor packaging and application laboratories in Asia, enabling rapid commercialization and supporting the mass deployment of Boston Materials’ technology in the APAC region.

- Industry analysts interpret the alliance as a major step for Mitsubishi Chemical Group to strengthen its role as a premier supplier in the rapidly evolving semiconductor value chain, and to capitalize on rising demand for AI and high-performance computing hardware.

- The collaboration is positioned to set new benchmarks for reliability and efficiency in semiconductor packaging, helping data center operators and chip manufacturers push the boundaries of compute density and uptime.

- Market observers are watching closely for commercial deployments and customer adoption, with the partnership likely to have a ripple effect on peer companies in the advanced materials and semiconductor sectors.

- Both companies are betting on the broader adoption of liquid metal TIMs to drive future growth, with ambitions to expand their influence across additional high-density, high-heat applications in technology and industry.

- If successful, the Mitsubishi Chemical Group and Boston Materials alliance could shift industry standards for chip cooling and create new competitive dynamics among materials suppliers and semiconductor integrators.

Discover more from Business-News-Today.com

Subscribe to get the latest posts sent to your email.