Northern Sun Energy has announced the construction of a behind-the-meter clean energy project in Illinois that will directly supply electricity to Prysmian’s cable manufacturing plant in Du Quoin. The project, developed in collaboration with distributed energy firm PowerFlex, includes a 7.5 megawatt-peak (MWp) fixed-tilt solar array paired with a 1 megawatt (MW) battery energy storage system using Tesla Megapack 2XL technology. Designed to meet up to 50 percent of the facility’s electricity needs, the system represents a rare example of industrial-scale solar-plus-storage deployment designed to support both manufacturing operations and local grid stability.

The development also marks Northern Sun Energy’s formal entry into the Midcontinent Independent System Operator (MISO) market. The Florida-based clean energy firm has historically focused on projects in the Southeastern United States but is now expanding geographically through high-impact industrial partnerships. According to Northern Sun Energy’s Vice President of Construction Operations and Managing Partner Scott Pfaff, this project reflects the company’s broader goal of delivering well-engineered clean energy systems that help regional manufacturers meet climate targets while strengthening resilience.

Prysmian’s Du Quoin facility, which produces medium-voltage copper cable used in renewable energy applications, will benefit from both energy cost reduction and emissions cuts. The solar-plus-storage system will also generate renewable energy credits under Illinois’ clean energy incentive framework, allowing Prysmian to participate in the Illinois Shines program while advancing its net zero 2035 goals.

Why Prysmian’s Du Quoin factory is turning to on-site solar for operational decarbonization

The Du Quoin manufacturing facility holds strategic importance for Prysmian North America. It supplies medium-voltage copper cables essential for energy infrastructure and data center projects, including those linked to renewable energy installations. Given the plant’s role in electrification value chains, deploying a solar-powered generation system directly on-site creates both environmental and branding advantages.

Paul Furtado, Chief Operating Officer of Prysmian North America, said the clean energy partnership with Northern Sun Energy and PowerFlex aligns with the company’s broader sustainability strategy. He noted that the Du Quoin plant’s solar array will meet approximately half of its power needs, enabling significant reductions in electricity consumption from the grid. According to Prysmian’s current roadmap, the firm aims to reduce Scope 1 and 2 greenhouse gas emissions by 90 percent and reach net zero emissions across its supply chain by 2035.

By shifting toward localized clean power, Prysmian also gains flexibility in managing operational loads and reduces exposure to potential utility rate hikes, time-of-use pricing, or unplanned outages. This type of direct energy sourcing is particularly critical for cable manufacturing operations, which require stable power flows to support continuous extrusion and annealing processes.

How Northern Sun Energy is entering the MISO market with industrial-scale energy projects

For Northern Sun Energy, the Prysmian deployment represents a major step in geographic diversification. The project is the firm’s first in the Midwest and establishes a foundational presence in the MISO territory, one of the most active U.S. markets for utility and industrial energy infrastructure.

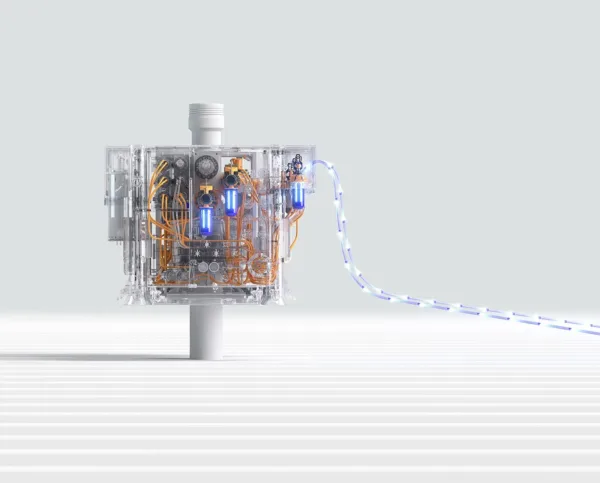

Scott Pfaff emphasized the importance of engineering clean energy systems that are tailored to industrial site needs. The Du Quoin installation includes more than 10,800 solar modules and a Tesla Megapack 2XL battery system with a capacity of 1,050 kilovolt-amperes (kVA). This design enables on-site power generation during daylight hours while storing excess energy for use during production spikes or grid stress events.

Pfaff also highlighted the role of community benefits in project execution. Local tradespeople were hired for construction work, helping generate employment in the Du Quoin area. The project’s grid-side value includes reduced peak demand, improved load balancing, and participation in regional renewable energy credit programs.

PowerFlex, a distributed energy developer with prior experience working with Northern Sun Energy, served as the project’s development partner. The collaboration builds on past successful engagements and positions both firms for additional industrial solar-plus-storage deployments in the Midwest and beyond.

Why behind-the-meter solar and battery systems are gaining traction with U.S. manufacturers

Unlike traditional off-site solar power purchase agreements, the Prysmian system will operate behind-the-meter, meaning the generated electricity is consumed on-site rather than exported to the grid. This model allows for greater control over energy use and immediate operational benefits, including power quality improvements and load shaping.

The use of Tesla’s Megapack 2XL battery platform adds another layer of sophistication. Designed for industrial and utility-scale applications, the Megapack 2XL provides scalable energy storage that can be configured to support site-specific loads. In this case, the battery’s 1 MW capacity ensures that stored energy can be dispatched during non-solar hours or used to offset peak demand charges.

Such systems are especially attractive for heavy industry, where energy-intensive operations and round-the-clock production cycles make reliability paramount. The resilience benefits alone can justify the capital expenditure in environments where even brief outages could cause manufacturing disruptions or equipment damage.

From a policy perspective, the project’s participation in the Illinois Shines program strengthens its financial profile. The initiative, managed by the Illinois Power Agency, provides compensation for renewable energy credits generated by solar projects. This makes the Du Quoin installation not only a sustainability milestone but also a revenue-generating asset for Prysmian.

How the Illinois Shines program supports industrial clean energy transitions

Illinois Shines is one of several state-level clean energy programs in the United States that incentivize distributed generation projects through renewable energy credits. By enrolling the Du Quoin solar project into the program, Prysmian will be able to monetize each megawatt-hour of clean electricity produced through the sale of RECs.

This additional revenue stream enhances the return on investment for the project while supporting broader decarbonization goals in Illinois. It also reflects an evolution in how manufacturing firms are approaching ESG mandates, moving away from symbolic climate action to direct, infrastructure-backed emissions reductions.

With Northern Sun Energy’s engineering expertise and PowerFlex’s development capabilities, the project is positioned as a replicable model for other industrial facilities across Illinois, Indiana, and neighboring states within the MISO footprint.

How are investors evaluating the strategic value of industrial solar and storage projects as corporate decarbonization accelerates?

While Northern Sun Energy remains a private company, the success of this project is likely to boost its visibility with infrastructure investors and clean energy financiers. Institutional sentiment toward distributed solar-plus-storage projects has become increasingly positive, particularly for deals involving large industrial off-takers with long operating horizons.

Projects that combine grid support, tenant demand offset, and participation in credit markets are also seen as more bankable. Prysmian’s investment-grade reputation, along with its publicly stated emissions reduction targets, provides assurance to potential capital partners seeking exposure to climate-resilient infrastructure.

The use of Tesla Megapack units adds a premium component to the project, further increasing its attractiveness as an asset class. These energy storage units are rapidly becoming the industry standard for large-scale battery deployments, offering performance benchmarks and integration capabilities that align with long-term investor needs.

Energy analysts tracking Midwestern industrial sectors anticipate an increase in similar projects throughout 2026, particularly as older grid assets face reliability constraints and clean energy adoption becomes both a business imperative and a regulatory expectation.

How will behind the meter solar and storage reshape industrial energy planning in 2026 and beyond?

Looking ahead, the Prysmian project is likely to be viewed as a blueprint for future behind-the-meter energy strategies. As utility interconnection timelines remain constrained for larger projects, on-site systems offer a faster path to clean energy adoption with measurable operational impact.

For Northern Sun Energy, the successful execution in Du Quoin opens doors for replicating the model in other regions with high industrial demand, available land, and supportive clean energy policies. For Prysmian, the project moves the company meaningfully closer to its climate targets while reinforcing its market position as a forward-thinking industrial manufacturer aligned with the energy transition.

The solar-plus-storage system is scheduled for full interconnection and activation by December 2025.

What are the key takeaways from Prysmian’s solar and battery deployment in Du Quoin, Illinois?

- Northern Sun Energy and PowerFlex are building a 7.5 MWp solar array and 1 MW Tesla Megapack 2XL battery system for Prysmian Group’s cable manufacturing plant in Du Quoin, Illinois.

- The project will directly supply up to 50 percent of the plant’s power needs, reducing grid reliance and supporting Prysmian’s decarbonization strategy.

- It marks Northern Sun Energy’s first project in the MISO market, expanding its footprint into the U.S. Midwest through industrial clean energy partnerships.

- The battery storage system is designed to deliver load-shaping capabilities and energy resilience during peak demand or grid disruptions.

- Prysmian will participate in the Illinois Shines program by generating and selling renewable energy credits, improving project ROI.

- Over 10,800 solar modules will be deployed on-site, with completion and interconnection targeted for December 2025.

- Local job creation during the project’s construction phase is contributing to regional economic development in Du Quoin.

- The project aligns with Prysmian’s net zero target across its value chain by 2035 and a 90 percent reduction in Scope 1 and 2 emissions.

- Investor sentiment toward behind-the-meter industrial renewable projects is improving due to stable demand, ESG alignment, and grid relief value.

- The Du Quoin project may become a replicable model as U.S. manufacturers accelerate adoption of site-specific clean energy infrastructure.

Discover more from Business-News-Today.com

Subscribe to get the latest posts sent to your email.